Papers

GIMOTA connectors with EMC connection technology for high leakage currents

Solutions for professional EMC shield taps as an important contribution to fail-safety

In Switzerland, most railways run on alternating current, whose frequency is 16.7 Hertz (Hz). The overhead lines of the railways generate electric and magnetic fields. As the current in the overhead lines is not always the same, the magnetic fields are subject to fluctuations. When locomotives and railcars accelerate or feed electricity back into the grid when braking, the current flow is greater and with it the magnetic field. On an ascending track or when pulling a heavy goods train, the locomotives also need more current, which in turn has an influence on the magnetic field.

On-board voltages of over 1000V, the inverter and DC converter often cause EMC interference in the area of the shielded high-voltage cables. In addition, load and speed changes exacerbate the EMC problem. The most common cause of EMC interference is a defective shield connection. That is why the correct shield connection is of central importance for connectors. Poor shield connection or shield components that are designed too weakly are responsible for weakening the entire system. Gimota circular connectors for EMC applications therefore have special shielding springs “grounding fingers” for seamless 360° transmission of shielding currents from the connector to the receptacle. The shield currents are thus optimally discharged via the connector housing. In addition, different shield connection variants for the connector termination ensure an excellent shield connection.

|

|

|

• Suitable for railway applications |

• Bayonet locking |

GIMOTA EMC connection with shielding sleeve

The GIMOTA EMC connection with shielding sleeve guarantees safe 360° shield contacting at the smallest space. The shielding concept with a shielding sleeve guarantees a high level of process reliability, as the components and crimping tools used are precisely defined and consistent with each other.

Low contact resistances

By crimping the shielding sleeve onto the shield, a direct contact from the braiding to the backshell is given. This results in extremely low contact resistances and high leakage currents.

Vibration safety

The defined crimping of the shielding sleeve, with the corresponding Gimota crimping tool, guarantees the highest vibration safety.

GIMOTA EMC connection with conical ring

The GIMOTA EMC connection with conical ring enables shield contacting of 360° with the shielding braid ending in the backshell. The edge geometry of the cone ring prevents the shielding braid from shearing off.

Smallest contact resistances

The 360° cone ring ensures the smallest contact resistance.

Permanent contact pressure

A permanent contact pressure of the shielding braid on the backshell is guaranteed by screwing the cone ring.

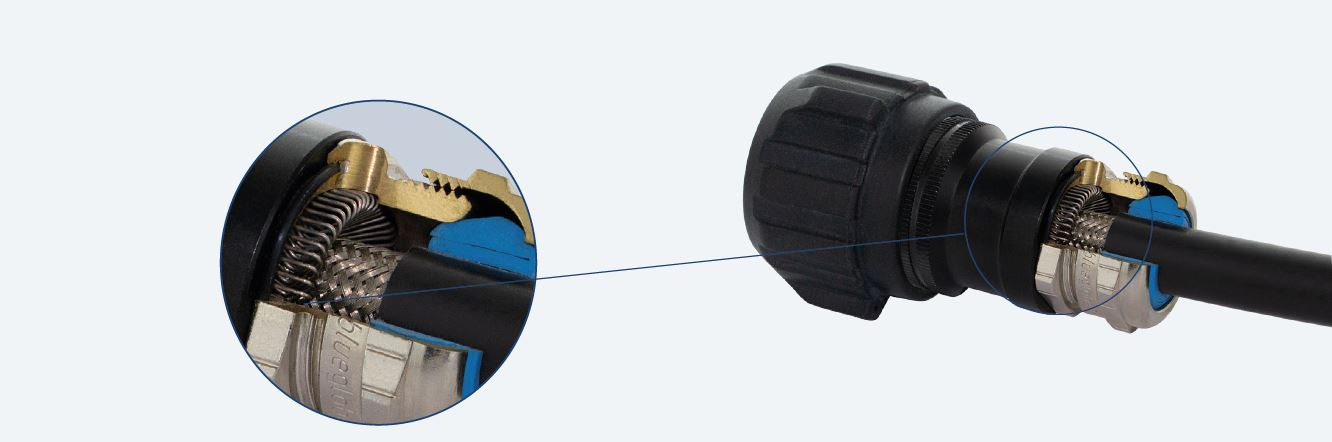

GIMOTA EMC connection with IRIS spring

The GIMOTA EMC connector with iris spring enables good and safe shield contacting of 360° with both partially stripped and fully exposed cable shields. The advantage of a shield spring compared to a shield compression is the higher flexibility in cable selection.

Optimum shield contacting

The powerful clamping of the cable shield via the shield spring guarantees excellent shield contact and ensures low transfer impedances.

Flexible contacting options

The iris spring optimally compensates for different shield thicknesses.

GIMOTA EMC connection with EMC cable gland

Of course, it is also possible to use a connector with a backshell with internal thread, the shielding can then be realized via an EMC cable gland.

Flexible contacting options

Due to the large variety of “high-end” cable glands, the customer is guaranteed to find the right solution for every cable.

Highest flexibility

The customer has the option of using a product he is already familiar with, from a well-known manufacturer.

GIMOTA EMC connection for two shielded cables

The GIMOTA EMC connection for two shielded cables with the same shielding potential enables good and safe shield contacting of 360° with both partially stripped and fully exposed cable shields.

Permanent contact pressure

A permanent contact pressure of the shielding braid on the backshell is guaranteed by screwing the shield clamp.

Tailor-made solution

This solution is adapted to the customer‘s needs and cables together with the customer, whereby both clean strain relief and the connection of a corrugated conduit are possible.

GIMOTA custom EMC connection

Customer-specific requirements, such as shielded cables and shielded protective conduit with different shield currents, can also be implemented.

1. Flexible contacting options

The iris spring optimally compensates for different shield thicknesses.

2. Shielding interruption

A special intermediate piece separates the different shielding potentials of the cable and the protective conduit.

3. Hose screw connection

The hose fitting ideally fixes the armoured protective hose.

To the Products

| Shield connection with shielding sleeve | Shield connection with cone ring | Shield connection with iris spring |

|

|

|