Service

Grinding patterns and micrograph examination

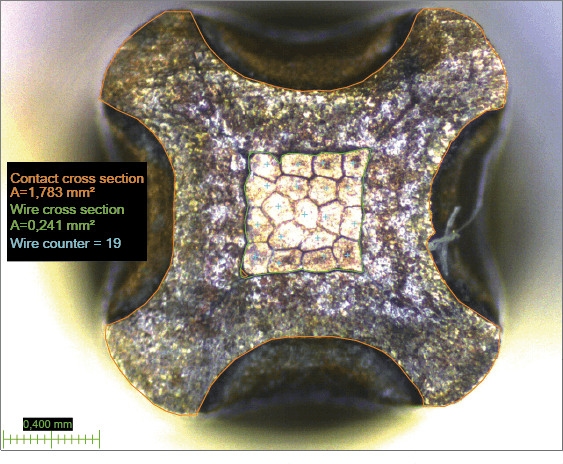

Cable assemblies for the railway industry must meet the highest of quality standards. A grinding pattern and micrograph analysis (analysis of the grinding surface) can indicate quality deficiencies, which have been caused, e.g. by wear and tear of the tools, temperature differences and in particular, by a change of tools or change of material.

A grinding pattern analysis provides microscopically precise insight into the quality. In the process, it is furthermore examined how even a crimped contract has been pressed and if it is gas-tight. The most optimal crimping assures the lowest the resistance of the line.

We recommend this test procedure for each new crimp connection because it guarantees continuous and safe crimp connections, especially under strong currents and vibrations. The tools can be qualified as a safe connection for the use with the intended wire type and the intended contact size only through a grinding pattern analysis.